Picking the Right Fiber Connector – UPC or APC?

You may often read things like LC/APC simplex singlemode connector or SC/UPC simplex singlemode connector. When looking at this LC to LC patch cable page, we can also find descriptions like “LC UPC to LC UPC duplex 10G OM4 multimode fiber optic patch cable”. What do all those words mean? Specifically UPC and APC. In fact, UPC and APC are two polish types of fiber ferrules. This article will help you explore the world of UPC and APC to decide which one is suitable for your network.

To help us better understand all this jargon, let’s look back at why the original Flat Fiber Connector evolved into the Physical Contact (PC) connector and then onto UPC and APC.

Ultra Physical Contact (UPC) is building on the convex end-face attributes of the Physical Contact (PC), but utilizing an extended polishing method creates an even finer fiber surface finish: bringing us the UPC connector. This results in a lower back reflection (ORL) than a standard PC connector, allowing more reliable signals in digital TV, telephony and data systems, where UPC today dominates the market.

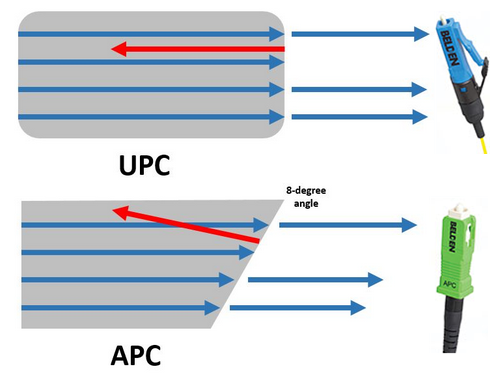

The end face of Angled Physical Contact (APC) connector is precisely polished at an 8-degree angle to the fiber cladding so that most return loss is reflected into the cladding where it cannot interfere with the transmitted signal or damage the laser source. But it is extremely difficult to field terminate an APC connector at 8 degrees with any consistent level of success. Therefore, if an APC connector is damaged in the field, it should be replaced with a factory terminated APC connector.

- End Faces — As we have discussed before, UPC connectors are polished with no angle, but APC connectors is polished at an 8-degree angle.

- Ways of Light Reflection — Their different polish end faces directly lead to their differences in ways of light reflection. Any reflected light is reflected straight back towards the light source if an UPC connector is used. But the APC connector causes reflected light to reflect at an angle into the cladding instead of straight back toward the source.

- Return Loss — Since their light reflection patterns are varied, their levels of return loss are also different. APC connector offers lower return loss of -65 dB than UPC of -50 dB. As a matter of fact, connectors can achieve better matching performance if return loss is lower.

- Connector Color — This is the most obvious difference that can be seen from the surface. UPC connector usually has a blue body while APC connector has a green body.

Looking at current technology, it’s clear that all of the connector end-face options mentioned above have a place in the market. Indeed, if we take a sidestep across to Plastic Optical Fiber (POF) applications, this can be terminated with a sharp craft knife and performance is still deemed good enough for use in the high-end automotive industry. When your specification also needs to consider cost and simplicity, not just optical performance, it’s hard to claim that one connector beats the others.

Therefore when it comes to fiber optic jumpers, whether you choose UPC or APC will depend on your particular need. With those applications that call for high precision optical fiber signaling, APC should be the first consideration, but less sensitive digital systems will perform equally well using UPC.